2 1/16 api flange dimensions

| Flange Size/Rating | Weld Neck Dimensions (Inches) | Flange-Material and Yield | Matching ANSI pipe size, schedule & yield PSI (K) | ||

|---|---|---|---|---|---|

| OD | ID | H | |||

| 1 13/16in 10M | 2.56 | 1.813 | 4.13 | Low Alloy 60K | Custom Pipe/Tubing 60K |

| *Indicates a heavier schedule pipe may be required – check pipe CWP with your pipe supplier. Items shown with asterix indicates a higher schedule could be required as follows:- | |||

| *1 Sched 80 | *2 Sched 100 | *3 Sched 120 | *4 Sched 140 |

| *5 Sched 160 | *6 Sched XXS | *7 Custom Pipe | |

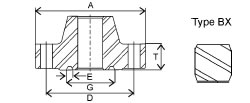

Dimension of 10000PSI(69.0MPA) type 6BX blind/Welding Neck API 6A Flange

| Size | B | OD | C | E1 | Q | G | K | T | J1 | J2 | J3 | J4 | R | BC | N | H | BX |

| 1 13/16″ | 46.8 | 185 | 3 | – | 5.56 | 77.77 | 105 | 42.1 | 88.9 | 65.1 | 48.5 | – | 10 | 146.1 | 8 | 23 | 151 |

| 2 1/16″ | 53.2 | 200 | 3 | – | 5.95 | 86.23 | 111 | 44.1 | 100 | 74.7 | 51.6 | – | 10 | 158.8 | 8 | 23 | 152 |

| 2 9/16″ | 65.9 | 230 | 3 | – | 6.75 | 102.77 | 132 | 51.2 | 120.7 | 92.1 | 57.2 | – | 10 | 184.2 | 8 | 26 | 153 |

| 3 1/16″ | 78.6 | 270 | 3 | – | 7.54 | 119 | 152 | 58.4 | 142.1 | 110.2 | 63.5 | – | 10 | 215.9 | 8 | 29 | 154 |

| 4 1/16″ | 104 | 315 | 3 | – | 8.33 | 150.62 | 185 | 70.3 | 182.6 | 146.1 | 73.1 | – | 10 | 258.8 | 8 | 32 | 155 |

| 5 1/8″ | 131 | 360 | 3 | 9.5 | 9.53 | 176.66 | 221 | 79.4 | 223.8 | 182.6 | 81 | 6.4 | 10 | 300 | 12 | 32 | 169 |

| 7 1/16″ | 180.2 | 480 | 6 | 11.1 | 11.11 | 241.83 | 302 | 103.2 | 301.6 | 254 | 95.3 | 9.7 | 16 | 403.2 | 12 | 42 | 156 |

| 9 “ | 229.4 | 550 | 6 | 12.7 | 12.7 | 299.06 | 359 | 123.9 | 374.7 | 327.1 | 93.7 | 9.7 | 16 | 476.3 | 16 | 42 | 157 |

| 11″ | 280.2 | 655 | 6 | 14.3 | 14.29 | 357.23 | 429 | 141.3 | 450.9 | 400.1 | 103.2 | 14.2 | 16 | 565.2 | 16 | 48 | 158 |

| 13 5/8″ | 346.9 | 770 | 6 | 15.9 | 15.88 | 432.64 | 518 | 168.3 | 552.5 | 495.3 | 114.3 | 17.5 | 16 | 673.1 | 20 | 51 | 159 |

| 16 3/4″ | 426.2 | 870 | 6 | 8.3 | 8.33 | 478.33 | 576 | 168.3 | 655.6 | 601.7 | 76.2 | 30.2 | 19 | 776.3 | 24 | 51 | 162 |

| 18 3/4″ | 477 | 1040 | 6 | 18.3 | 18.26 | 577.9 | 697 | 223.1 | 752.5 | 674.7 | 155.6 | 25.4 | 16 | 925.5 | 24 | 61 | 164 |

| 21 1/4″ | 540.5 | 1145 | 6 | 19.1 | 19.05 | 647.88 | 781 | 241.3 | 847.7 | 762 | 165.1 | 31.8 | 21 | 1022.4 | 24 | 67 | 166 |

13 5 8 api flange

Dimension of AISI 4130 5000PSI(34.5MPA) type 6BX Blind API 6A Flange

| Size | OD | C | E1 | G | K | T | J1 | J4 | R | BC | N | H | BX |

| 13 5/8″ | 675 | 6 | 14.3 | 408 | 457 | 112.8 | 481 | 23.9 | 16 | 590.6 | 16 | 45 | 160 |

| 16 3/4″ | 770 | 6 | 8.3 | 478.33 | 535 | 130.2 | 555.6 | 17.5 | 19 | 676.3 | 16 | 51 | 162 |

| 18 3/4″ | 905 | 6 | 18.3 | 563.5 | 627 | 165.9 | 674.7 | 19.1 | 16 | 803.3 | 20 | 54 | 163 |

| 21 1/4″ | 990 | 6 | 19.1 | 632.56 | 702 | 181 | 758.8 | 22.4 | 18 | 885.8 | 24 | 54 | 165 |

1. RING NUMBER BX, 2. C should be the max value 3. Tolerance and Ring Gasket according to API 6A-20TH

api weld on flange manufacturers

Jayant Impex offer a large range of API 6A and ANSI forged swivel flanges, Blind flanges, slip-on flanges and weld-neck flanges in 4130 carbon steel, to suit 2” to 6” nominal bore XXS pipe with pressure rating below. The API 6A specification requires a rigorous and unique quality system including stringent dimensional and NDT control. The application of an API monogram is that you, the client will be guaranteed of total compliance with the API specifications

Weld Neck Flanges

| Min. Yield | 45,000 PSI | 45,000 PSI | 45,000 PSI | 60,000 PSI | 75,000 PSI | 75,000 PSI |

| Min. Tensile | 70,000 PSI | 70,000 PSI | 70,000 PSI | 85,000 PSI | 95,000 PSI | 95,000 PSI |

| Material | API 45K | API 45K | API 45K | API 60K | API 75K | API 75K |

api swivel flange weights

The Swivel-Ring Flange permits 360° rotation of an outer ring around a hub, to allow easy alignment of bolt holes when attaching to a mating standard flange. For subsea applications, this capability is important when only a single diver is available to align and make up the flange connection.

Swivel-Ring Flanges can be designed for any size and pressure rating to meet applicable dimensions and gasket types of any recognized flange specification, such as ASME B16.5, API 6A or MSS SP-44.

Design Specifications

Swivel-Ring Flanges meet the requirements of API 6H and are designed in accordance with ASME Pressure Vessel Code, Section VIII, Division 2, unless otherwise specified, and applicable sections of the flange specification to which it will mate.

api flange weld neck manufacturers

API Specified 6B Weld Neck Flanges have restricted bores to match standard pipe sizes and schedules. API Spec 6A Specified, 6 BX Weld Neck Flanges, have material and dimensions that conform to the requirements for full bore integral flanges. API Spec 6A does not specify overall length of 6BX Weld Neck Flanges, but instead provides dimensions of specific portions of the flange, with tolerance, that are added together, along with an undefined weld bevel, to achieve a length. Customers may specify weld neck length if required.

10000psi blind flange manufacturers

| Flanges for Wellhead and Christmas Tree EquipmentWeld Neck, Integral, Blinds, Targets and Test Blinds – Pressure Ratings – | ||||||

| MaximumWorking

Pressure |

2000PSI | 3000PSI | 5000PSI | 10000PSI | 15000PSI | 20000PSI |

| Test Pressure | 3000 PSI | 4500 PSI | 7500 PSI | 15000 PSI | 22500 PSI | 30000 PSI |

| ProductSpecification

Levels |

1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 |

| APITemperature

Rating |

K (-60 Deg C)to

Y(+345 Deg C) |

K (-60 Deg C)to

Y(+345 Deg C) |

K (-60 Deg C)to

Y(+345 Deg C) |

K (-60 Deg C)to

Y(+345 Deg C) |

K (-60 Deg C)to

Y(+345 Deg C) |

K (-60 Deg C)to

Y(+345 Deg C) |

15000psi 6BX WN/BL Flange Manufacturers

| API Flanges Datasheet | ||||||

| Max. Working Pressure | 15,000 PSI | |||||

| Test Pressure | 22,500 PSI | |||||

| Product Specification Levels | 1, 2, 3 & 4 | |||||

| API Temperature Rating | K (-60 Deg C) | |||||

| To | ||||||

| Y (+345 Deg C) | ||||||

20000psi 6BX WN/BL Flange Manufacturers

| Flanges for Wellhead and Christmas Tree EquipmentWeld Neck, Integral, Blinds, Targets and Test Blinds – Pressure Ratings – | ||||||

| MaximumWorking

Pressure |

20000PSI | |||||

| Test Pressure | 30000 PSI | |||||

| ProductSpecification

Levels |

1, 2, 3 & 4 | |||||

| APITemperature

Rating |

K (-60 Deg C)to

Y(+345 Deg C) |

|||||

api 75k flange Manufacturers

| Integral, Blind, Target Blind & Test Flanges | ||||||

| Min. Yield | 60000 PSI | 60000 PSI | 60000 PSI | 60000 PSI | 75000 PSI | 75000 PSI |

| Min. Tensile | 85000 PSI | 85000 PSI | 85000 PSI | 85000 PSI | 95000 PSI | 95000 PSI |

| Material | API 60K | API 60K | API 60K | API 60K | API 75K | API 75K |

| Weld Neck Flanges | ||||||

| Min. Yield | 45000 PSI | 45000 PSI | 45000 PSI | 60000 PSI | 75000 PSI | 75000 PSI |

| Min. Tensile | 70000 PSI | 70000 PSI | 70000 PSI | 85000 PSI | 95000 PSI | 95000 PSI |

| Material | API 45K | API 45K | API 45K | API 60K | API 75K | API 75K |

api flange pressure rating chart

| APIPressure

Rating |

Flange | Ring Groove | Bolt Studs | ||||||||||||||

| Nominal Size | Outside Diameter | T | P | E Width | Ring No | D Bolt Circle | No. | Size | Stud Length | ||||||||

| in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | ||||

| 2000 psi13.8 MPa

(R or RX Gasket) |

21/16 | 52.4 | 61/2 | 165 | 15/16 | 33.3 | 31/4 | 82.55 | 15/32 | 11.91 | 23 | 5 | 127.0 | 8 | 5/8 | 41/2 | 108 |

| 29/16 | 65.1 | 71/2 | 191 | 17/16 | 36.5 | 4 | 101.60 | 15/32 | 11.91 | 26 | 57/8 | 149.2 | 8 | 3/4 | 5 | 127 | |

| 31/8 | 79.4 | 81/4 | 210 | 19/16 | 39.7 | 47/8 | 123.83 | 15/32 | 11.91 | 31 | 65/8 | 168.3 | 8 | 3/4 | 51/4 | 133 | |

| 41/16 | 103.2 | 103/4 | 273 | 113/16 | 46.0 | 57/8 | 149.23 | 15/32 | 11.91 | 37 | 81/2 | 215.9 | 8 | 7/8 | 6 | 152 | |

| 51/8 | 130.0 | 13 | 330 | 21/16 | 52.4 | 71/8 | 180.98 | 15/32 | 11.91 | 41 | 101/2 | 266.7 | 8 | 1 | 63/4 | 165 | |

| 71/16 | 179.4 | 14 | 356 | 23/16 | 55.6 | 85/16 | 211.14 | 15/32 | 11.91 | 45 | 111/2 | 292.1 | 12 | 1 | 7 | 178 | |

| 9 | 228.6 | 161/2 | 419 | 21/2 | 63.5 | 105/8 | 269.88 | 15/32 | 11.91 | 49 | 133/4 | 349.3 | 12 | 11/8 | 8 | 203 | |

| 11 | 279.4 | 20 | 508 | 213/16 | 71.4 | 123/4 | 323.85 | 15/32 | 11.91 | 53 | 17 | 431.8 | 16 | 11/4 | 83/4 | 222 | |

| 135/8 | 346.1 | 22 | 559 | 215/16 | 74.6 | 15 | 381.00 | 15/32 | 11.91 | 57 | 191/4 | 489.0 | 20 | 11/4 | 9 | 229 | |

| 163/4 | 425.5 | 27 | 686 | 35/16 | 84.1 | 181/2 | 469.90 | 15/32 | 11.91 | 65 | 233/4 | 603.3 | 20 | 11/2 | 101/4 | 260 | |

| 211/4 | 539.8 | 32 | 813 | 37/8 | 98.4 | 23 | 584.20 | 17/32 | 13.49 | 73 | 281/2 | 723.9 | 24 | 15/8 | 113/4 | 298 | |

| 3000 psi20.7 MPa

(R or RX Gasket) |

21/16 | 52.4 | 81/2 | 216 | 113/16 | 46.0 | 33/4 | 95.25 | 15/32 | 11.91 | 24 | 61/2 | 165.1 | 8 | 7/8 | 6 | 152 |

| 29/16 | 65.1 | 95/8 | 244 | 115/16 | 49.2 | 41/4 | 107.95 | 15/32 | 11.91 | 27 | 71/2 | 190.5 | 8 | 1 | 61/2 | 165 | |

| 31/8 | 79.4 | 91/2 | 241 | 113/16 | 46.0 | 47/8 | 123.83 | 15/32 | 11.91 | 31 | 71/2 | 190.5 | 8 | 7/8 | 6 | 152 | |

| 41/16 | 103.2 | 111/2 | 292 | 21/16 | 52.4 | 57/8 | 149.23 | 15/32 | 11.91 | 37 | 91/4 | 235.0 | 8 | 11/8 | 7 | 178 | |

| 51/8 | 130.0 | 133/4 | 350 | 25/16 | 58.8 | 71/8 | 180.98 | 15/32 | 11.91 | 41 | 11 | 279.4 | 8 | 11/4 | 73/4 | 195 | |

| 71/16 | 179.4 | 15 | 381 | 21/2 | 63.5 | 85/16 | 211.14 | 15/32 | 11.91 | 45 | 121/2 | 317.5 | 12 | 11/8 | 8 | 203 | |

| 9 | 228.6 | 181/2 | 470 | 213/16 | 71.4 | 105/8 | 269.88 | 15/32 | 11.91 | 49 | 151/2 | 393.7 | 12 | 13/8 | 9 | 229 | |

| 11 | 279.4 | 211/2 | 546 | 31/16 | 77.8 | 123/4 | 323.85 | 15/32 | 11.91 | 53 | 181/2 | 469.9 | 16 | 13/8 | 91/2 | 241 | |

| 135/8 | 346.1 | 24 | 610 | 37/16 | 87.3 | 15 | 381.00 | 15/32 | 11.91 | 57 | 21 | 533.4 | 20 | 13/8 | 101/4 | 260 | |

| 163/4 | 425.5 | 273/4 | 705 | 315/16 | 100.0 | 181/2 | 469.90 | 21/32 | 16.67 | 66 | 241/4 | 616.0 | 20 | 15/8 | 113/4 | 298 | |

| 203/4 | 527.1 | 333/4 | 857 | 43/4 | 120.7 | 23 | 584.20 | 25/32 | 19.84 | 74 | 291/2 | 749.3 | 20 | 2 | 141/2 | 368 | |

| 5000 psi34.5 MPa

(R or RX Gasket) |

21/16 | 52.4 | 81/2 | 216 | 113/16 | 46.0 | 33/4 | 95.25 | 15/32 | 11.91 | 24 | 61/2 | 165.1 | 8 | 7/8 | 6 | 152 |

| 29/16 | 65.1 | 95/8 | 244 | 115/16 | 49.2 | 41/4 | 107.95 | 15/32 | 11.91 | 27 | 71/2 | 190.5 | 8 | 1 | 61/2 | 165 | |

| 31/8 | 79.4 | 101/2 | 267 | 23/16 | 55.6 | 53/8 | 136.53 | 15/32 | 11.91 | 35 | 8 | 203.2 | 8 | 11/8 | 71/4 | 184 | |

| 41/16 | 103.2 | 121/4 | 311 | 27/16 | 61.9 | 63/8 | 161.93 | 15/32 | 11.91 | 39 | 91/2 | 241.3 | 8 | 11/4 | 8 | 203 | |

| 51/8 | 130.0 | 143/4 | 375 | 33/16 | 81.0 | 75/8 | 193.68 | 15/32 | 11.91 | 44 | 111/2 | 292.1 | 8 | 11/2 | 10 | 255 | |

| 71/16 | 179.4 | 151/2 | 394 | 35/8 | 92.1 | 85/16 | 211.14 | 17/32 | 13.49 | 46 | 121/2 | 317.5 | 12 | 13/8 | 103/4 | 273 | |

| 9 | 228.6 | 19 | 483 | 41/16 | 103.2 | 105/8 | 269.88 | 21/32 | 16.67 | 50 | 151/2 | 393.7 | 12 | 15/8 | 12 | 305 | |

| 11 | 279.4 | 23 | 584 | 411/16 | 119.1 | 123/4 | 323.85 | 21/32 | 16.67 | 54 | 19 | 482.6 | 12 | 17/8 | 133/4 | 349 | |

| APIPressure

Rating |

Flange | Ring Groove | Bolt Studs | ||||||||||||||

| Nominal Size | Outside Diameter | T | P | E Width | Ring No | D Bolt Circle | No. | Size | Stud Length | ||||||||

| in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | ||||

| 5000 psi34.5 MPa

(BX Gasket) |

135/8 | 346.1 | 261/2 | 673 | 47/16 | 112.7 | 16.063 | 408.00 | 0.786 | 19.96 | BX-160 | 231/4 | 590.6 | 16 | 15/8 | 121/2 | 318 |

| 163/4 | 425.5 | 303/8 | 772 | 51/8 | 130.2 | 18.832 | 478.33 | 0.705 | 17.91 | BX-162 | 265/8 | 676.3 | 16 | 17/8 | 141/2 | 368 | |

| 183/4 | 476.3 | 355/8 | 905 | 617/32 | 165.9 | 22.185 | 563.50 | 1.006 | 25.55 | BX-163 | 315/8 | 803.3 | 20 | 2 | 171/2 | 445 | |

| 211/4 | 539.8 | 39 | 991 | 71/8 | 181.0 | 24.904 | 632.56 | 1.071 | 27.20 | BX-165 | 347/8 | 885.8 | 24 | 2 | 183/4 | 476 | |

| 10,000 psi69.0 MPa

(BX Gasket) |

113/16 | 46.0 | 73/8 | 187 | 121/32 | 42.1 | 3.062 | 77.77 | 0.466 | 11.84 | BX-151 | 53/4 | 146.1 | 8 | 3/4 | 5 | 127 |

| 21/16 | 52.4 | 77/8 | 200 | 147/64 | 44.1 | 3.395 | 86.23 | 0.498 | 12.65 | BX-152 | 61/4 | 158.8 | 8 | 3/4 | 51/4 | 133 | |

| 29/16 | 65.1 | 91/8 | 232 | 21/64 | 51.2 | 4.046 | 102.77 | 0.554 | 14.07 | BX-153 | 71/4 | 184.2 | 8 | 7/8 | 6 | 152 | |

| 31/16 | 77.8 | 105/8 | 270 | 219/64 | 58.3 | 4.685 | 119.00 | 0.606 | 15.39 | BX-154 | 81/2 | 215.9 | 8 | 1 | 63/4 | 171 | |

| 41/16 | 103.2 | 127/16 | 316 | 249/64 | 70.2 | 5.930 | 150.62 | 0.698 | 17.73 | BX-155 | 103/16 | 258.8 | 8 | 11/8 | 8 | 203 | |

| 51/8 | 130.2 | 141/16 | 357 | 31/8 | 79.4 | 6.955 | 176.66 | 0.666 | 16.92 | BX-169 | 1113/16 | 300.0 | 12 | 11/8 | 83/4 | 222 | |

| 71/16 | 179.4 | 187/8 | 479 | 41/16 | 103.2 | 9.521 | 241.83 | 0.921 | 23.39 | BX-156 | 157/8 | 403.2 | 12 | 11/2 | 111/4 | 286 | |

| 9 | 228.6 | 213/4 | 552 | 47/8 | 123.8 | 11.774 | 299.06 | 1.039 | 26.39 | BX-157 | 183/4 | 476.3 | 16 | 11/2 | 13 | 330 | |

| 11 | 279.4 | 253/4 | 654 | 59/16 | 141.3 | 14.064 | 357.23 | 1.149 | 29.18 | BX-158 | 221/4 | 565.2 | 16 | 13/4 | 15 | 381 | |

| 135/8 | 346.1 | 301/4 | 768 | 65/8 | 168.3 | 17.033 | 432.64 | 1.279 | 32.49 | BX-159 | 261/2 | 673.1 | 20 | 17/8 | 171/4 | 438 | |

| 163/4 | 425.5 | 345/16 | 872 | 65/8 | 168.3 | 18.832 | 478.33 | 0.705 | 17.91 | BX-162 | 309/16 | 776.3 | 24 | 17/8 | 171/2 | 445 | |

| 183/4 | 476.3 | 4015/16 | 1040 | 825/32 | 223.0 | 22.752 | 577.90 | 1.290 | 32.77 | BX-164 | 367/16 | 925.5 | 24 | 21/4 | 221/2 | 572 | |

| 211/4 | 539.8 | 45 | 1143 | 91/2 | 241.3 | 25.507 | 647.88 | 1.373 | 34.87 | BX-166 | 401/4 | 1022.4 | 24 | 21/2 | 241/2 | 622 | |

| 15,000 psi103.5 MPa

(BX Gasket) |

113/16 | 46.0 | 83/16 | 208 | 125/32 | 45.2 | 3.062 | 77.77 | 0.466 | 11.84 | BX-151 | 65/16 | 160.3 | 8 | 7/8 | 51/2 | 140 |

| 21/16 | 52.4 | 83/4 | 222 | 2 | 50.8 | 3.395 | 86.23 | 0.498 | 12.65 | BX-152 | 67/8 | 174.6 | 8 | 7/8 | 6 | 152 | |

| 29/16 | 65.1 | 10 | 254 | 21/4 | 57.2 | 4.046 | 102.77 | 0.554 | 14.07 | BX-153 | 77/8 | 200.0 | 8 | 1 | 63/4 | 171 | |

| 31/16 | 77.8 | 115/16 | 287 | 217/32 | 64.3 | 4.685 | 119.00 | 0.606 | 15.39 | BX-154 | 91/16 | 230.2 | 8 | 11/8 | 71/2 | 191 | |

| 41/16 | 103.2 | 143/16 | 360 | 33/32 | 78.6 | 5.930 | 150.62 | 0.698 | 17.73 | BX-155 | 117/16 | 290.5 | 8 | 13/8 | 91/4 | 235 | |

| 71/16 | 179.4 | 197/8 | 505 | 411/16 | 119.1 | 9.521 | 241.83 | 0.921 | 23.39 | BX-156 | 167/8 | 428.6 | 16 | 11/2 | 123/4 | 324 | |

| 9 | 228.6 | 251/2 | 648 | 53/4 | 146.1 | 11.774 | 299.06 | 1.039 | 26.39 | BX-157 | 213/4 | 552.5 | 16 | 17/8 | 153/4 | 400 | |

| 11 | 279.4 | 32 | 813 | 73/8 | 187.3 | 14.064 | 357.23 | 1.149 | 29.18 | BX-158 | 28 | 711.2 | 20 | 2 | 191/4 | 489 | |

| 135/8 | 346.1 | 347/8 | 886 | 81/16 | 204.8 | 17.033 | 432.60 | 1.279 | 32.50 | BX-159 | 307/8 | 784.2 | 20 | 21/4 | 211/4 | 540 | |

| 183/4 | 476.3 | 453/4 | 1162 | 101/16 | 255.6 | 22.752 | 577.90 | 1.290 | 32.77 | BX-164 | 4 | 1016.0 | 20 | 3 | 263/4 | 679 | |

| 20,000 psi138.0 MPa

(BX Gasket) |

113/16 | 46.0 | 101/8 | 257 | 21/2 | 63.5 | 3.062 | 77.77 | 0.466 | 11.84 | BX-151 | 8 | 203.2 | 8 | 1 | 71/2 | 191 |

| 21/16 | 52.4 | 115/16 | 287 | 213/16 | 71.4 | 3.395 | 86.23 | 0.498 | 12.65 | BX-152 | 91/16 | 230.2 | 8 | 11/8 | 81/4 | 210 | |

| 29/16 | 65.1 | 1213/16 | 325 | 31/8 | 79.4 | 4.046 | 102.77 | 0.554 | 14.07 | BX-153 | 105/16 | 261.9 | 8 | 11/4 | 91/4 | 235 | |

| 31/16 | 77.8 | 141/16 | 357 | 33/8 | 85.7 | 4.685 | 119.00 | 0.606 | 15.39 | BX-154 | 115/16 | 287.3 | 8 | 13/8 | 10 | 254 | |

| 41/16 | 103.2 | 179/16 | 446 | 43/16 | 106.4 | 5.930 | 150.62 | 0.698 | 17.73 | BX-155 | 141/6 | 357.2 | 8 | 13/4 | 121/4 | 311 | |

| 71/16 | 179.4 | 2513/16 | 656 | 61/2 | 165.1 | 9.521 | 241.83 | 0.921 | 23.39 | BX-156 | 2113/16 | 554.0 | 16 | 2 | 171/2 | 445 | |

| 9 | 228.6 | 3111/16 | 805 | 81/16 | 204.8 | 11.774 | 399.06 | 1.039 | 26.39 | BX-157 | 27 | 685.8 | 16 | 21/2 | 223/8 | 568 | |

| 11 | 279.4 | 343/4 | 883 | 813/16 | 223.8 | 14.064 | 357.23 | 1.149 | 29.18 | BX-158 | 291/2 | 749.3 | 16 | 23/4 | 233/4 | 603 | |

| 135/8 | 346.1 | 353/4 | 1162 | 111/2 | 292.1 | 17.033 | 432.64 | 1.279 | 32.49 | BX-159 | 40 | 1016.0 | 20 | 31/8 | 30 | 762 | |

api flanges manufacturer video

xbcvnb

|

|

|

|

|

| 5000psi 6B WN/BL Flange | api flange raised face | api ring joint flange | api swivel flange weights | api flange pressure ratings |

|

|

|

|

|

| api flange suppliers | api ansi flange comparison | api 6bx 10000 flange | 30 api flange dimensions | 3000psi welding neck flange |