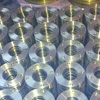

AISI 4130 Flanges Manufacturers

- Type: AISI 4130 Flanges

- Flanges Type:

- Alloy Steel AISI 4130 Forged Flanges ANSI B16.5 (Size 15 NB to 750 NB)

- Alloy Steel AISI 4130 Plate Flanges ANSI B16.5 (15 NB to 500 NB)

- Material: Alloy Steel AISI 4130, AISI 4140, AISI 4130 Flanges

- Standard: ANSI,JIS,DIN,BS4504,SABS1123,EN1092-1, UNI ,AS2129,GOST-12820

- Size: 1/2-78 inch (DN15-DN2000)

- Pressure: ANSI class 150,300,600,1500,2500, DIN PN6,PN10,PN16,PN25,PN40,PN64,PN100,PN160

- Test Certificate: Manufacturer Test Certificate, IBR Test Certificate (Form III-C), Under Third Party Inspection

- Packing: No Fumigate or Fumigate Plywood/Wood Pallet or Case

- Surface Treatment: Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint,Zinc,Hot dipped Galvanized.

- Usage: AISI 4130 Flanges mostly used in Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects etc

AISI 4140 Flanges Manufacturers

SAE AISI 4140 is low alloy Chrome Moly Steel for high temperature service. AISI 4140 is available in Round Bars, Forging Stock & Plate form. AISI 4140 Flanges is forged and machined from a suitable bar or forging stock, followed by material conformity testing, visual inspection, dimensional check, final non destructive tests, certifications, packing & shipping.

Commonly manufactured flange types from SAE 4140 are Blind, Slip-On, Threaded, Socket Weld, Weld Neck, Loose Plate Flange, Plate Blind, Vessel Cover Plate, Pressure Vessel Cover Blind Flange, etc.

SAE / AISI 4140 chemical composition, mechanical properties & other specifications.

Equivalent grades

| GB | DIN | AISI | JIS |

| 42CrMo | 1.7225 | 4140 | SCM440 |

Chemical Composition

| C | Si | Mn | Cr | Mo | P | S |

| 0.38-0.43 | 0.40max | 0.60-0.90 | 0.90-1.20 | 0.15-0.30 | ≤0.035 | ≤0.035 |

AISI 4340 Flanges Manufacturers

SAE AISI 4340 is low alloy Chrome Moly Steel for high temperature service. AISI 4340 is available in Round Bars, Forging Stock & Plate form. AISI 4340 Flanges is forged and machined from a suitable bar or forging stock, followed by material conformity testing, visual inspection, dimensional check, final non destructive tests, certifications, packing & shipping.

Commonly manufactured flange types from SAE 4340 are Blind, Slip-On, Threaded, Socket Weld, Weld Neck, Loose Plate Flange, Plate Blind, Vessel Cover Plate, Pressure Vessel Cover Blind Flange, etc.

SAE / AISI 4340 chemical composition, mechanical properties & other specifications.

Flange Type: 4340 Flanges are available in following types

- Slip On Flange

- Weld Neck Flange

- Socket Weld Flange

- Threaded Flange

- Blind Flange

- Lap Joint Flange

| Chemical Analysis | |

|---|---|

| C | Carbon 0.38 – 0.43 |

| Mn | Manganese 0.60 – 0.80 max |

| P | Phosphorus 0.035 max |

| S | Sulfur 0.04 max |

| Si | Silicon 0.15 – 0.30 |

| Ni | Nickel 1.65 – 2.00 |

| Cr | Chromium 0.70 – 0.90 |

| Mo | Molybdenum 0.20 – 0.30 |

alloy 20 12 point flange bolt

- Diameter:7/16"

- Diameter-Thread Size:7/16"-20

- Finish:Plain

- Head:12 Point Flanged

- Length:7/8"

- Material:Alloy Steel

- System of Measurement:Imperial (Inch)

- Thread:Fine

- Thread Size:20

- Type:Ferry Cap Screw

- Wrench Size:7/16"

- Product Weight: 0.06 lbs.

- Notes: 12-point head and flanged bearing surface. The external drive provides tighter wrenching with more gripping surface.The large gripping surface offers more torque and tighter wrenching by hand power. They can be installed and removed with a standard 12-point socket or pneumatic wrench. Rockwell hardness is C38-C42. Minimum tensile strength is 170,000 psi. Plain Finish, or bare metal finish which may contain a light coating of oil.

|

12-Point Flange Bolts

|

||||

|---|---|---|---|---|

|

Material

|

12-Point Flange Bolts Size

|

Length

|

Standard & Specification

|

12-Point Flange Bolts Manufacturer

|

|

M02 to M33

|

3 mm

to 200 mm |

|

|

alloy 20 blind flanges Manufacturers

Guru Gautam Steels are Manufacturers, Supplier and Exporters of Alloy 20 Flanges that is Fabricated From High Quality Raw Materials. These Alloy 20 Flange are engineered with utmost precision using latest machinery. These components are specifically designed to meet the demands of diverse industries. Alloy 20 Flanges are Available in different grades and sizes, shapes.

ANSI B16.47 Alloy 20 Blind Flanges, DIN 2.4617 ASTM B366 Plate Flanges, Alloy 20 N10665 Socket Weld Flanges & Weld Neck Flanges Manufacturer in india.

| Standard | Alloy 20 |

| UNS | N08020 |

| WERKSTOFF NR. | 2.4660 |

| EN | NiCr20CuMo |

| AFNOR | Z2NCUD31-20AZ |

Alloy 20 ANSI B16.5 / B16.47 Flanges Specification :

Standard : ASTM, ASME, ANSI, JIS, DIN, BSNA 11, EN Ni 99.2, JIS NW 2200, GOST-НП-2

Dimensions : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Designation : ASTM / ASME B 366 / SB 366

Class : Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 & Class 2500

Size : 1/2″NB TO 60″NB

Grades : Alloy 20 (UNS N10665) Flanges, 2.4617

Pressure : DIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

alloy 20 flange Manufacturers

Alloy 20 is one of the so-called "Super" stainless steels that was designed for maximum resistance to acid attack. It’s nickel, chromium, molybdenum and copper content contribute to its overall resistance to chlorideon stress corrosion cracking and general pitting attack. The alloy is stabilized with columbium to minimize carbide precipitation during welding. It has good mechanical properties and can be fabricated with comparative ease. Athough the alloy was designed for use in sulfuric acid related industries, it finds wide usage throughout the chemical processing industry. It also is used for processing pharmaceuticals, food, gasoline, solvents, plastics, explosives, synthetic fibers and many other products.

Specifications

| Standards | : | ASTM, ASME |

| Designation | : | B 366, SB 366 |

| Grade | : | Alloy 20 Flanges Alloy 20 Flanges: ASTM B 366, ASME SB 366 |

| Standard | Alloy 20 |

|---|---|

| UNS | N08020 |

| Werkstoff Nr. | 2.4660 |

Chemical Composition

| Alloy 20 | |

| Ni | 32 – 38 |

| Fe | Bal |

| Cr | 19 – 21 |

| Cu | 3 – 4 |

| Mo | 2 – 3 |

| Nb | 0.1 – 0.3 |

| C | 0.02 max |

| Mn | 1 – 2 |

| P | 0.02 max |

| S | 0.005 max |

| Si | 0.7 max |

Mechanical & Physical Properties – Alloy 20

| Density | 8.1 g/cm3 |

| Melting Point | 1443 °C (2430 °F) |

| Tensile Strength | Psi – 80000 , MPa – 551 |

| Yield Strength (0.2%Offset) | Psi – 35000 , MPa – 241 |

| Elongation | 30 % |

alloy 20 flange ratings

Alloy 20 Flanges

Forged and Plate Flanges

| UNS Grade | UNS N08020 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | ½” to 36″ |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Product | Size | |

| Alloy 20 Slip-On Flanges | Alloy 20 Threaded Flanges | 1/2″ – 36″Raised Face or Flat Face |

| Alloy 20 Weld Neck Flanges | Alloy 20 Socket Weld Flanges | |

| Alloy 20 Blind Flanges | Alloy 20 Reducing Flanges | |

| Alloy 20 Lap Joint Flanges | Alloy 20 Plate Flanges | |

alloy 20 flange specification

We are manufacturing Alloy 20 Alloy Flanges in all types like Slip on Flanges, Weld Neck Flanges, Long Weld Neck Flanges, Heavy Barrel Flanges in all pressure ratings. These all Alloy 20 Flanges we strictly manufacture as per international standards and norms. We do accept the order for the forged flanges as per customers design or samples as well.

Alloy 20 Flanges Dimensional Options:

We are manufacturing these Alloy 20 Flanges as per many international dimensional standards like :

- ASME standard Alloy 20 Flanges

- DIN standard Alloy 20 Flanges

- BS standard Alloy 20 Flanges

- JIS standard Alloy 20 Flanges

Alloy 20 Flanges Size Range :

- 1/2" NB ( DN 15) to 60" NB ( DN 1500)

| UNS Grade | UNS N08020 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | ½” to 36″ |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

Alloy Steel welding neck flanges manufacturers

Weld neck pipe flanges are connected to the pipe by welding the pipe to the neck of the pipe flange, which helps to pass on the stress from the weld neck to the pipe itself. This also reduces high stress concentration at the base of the hub of the weld neck pipe flanges. Weld neck pipe flanges are generally used in high pressure applications, where hot or cold temperatures exist. The inside diameter of a weld neck pipe flange is machined to match the inside diameter of the pipe.

We are well known for Alloy Steel Weld Neck flanges products. Advance technology and high quality materials are used to produce best & effective flanges. Alloy steel Weld Neck flanges are produced in different dimension, shape and size as per the requirement of our customer.

Standard : ASTM, ASME, ANSI, JIS, DIN, BSNA 11, EN Ni 99.2, JIS NW 2200, GOST-НП-2

Material:Alloy Steel Flanges: ASTM A182 F1, F5, F9, F11, F22, F91

Dimensions : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Class : Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 & Class 2500

Size : 1/2″NB TO 60″NB

Pressure : DIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

Alloy Steel socket welding flanges, Alloy Steel Socket Weld flanges manufacturers

Alloy Steel Flanges are available in Weld Neck, Slip-On, Threaded, Screwed, Socket Weld, Lap Joint, Blind, Long Weld Neck & Orifice type. These Alloy steel Flanges can be manufactured in size 1/2″ NPS to 60″ NPS as per different dimensional standards.

Socket weld flange is similar to the slip-on flange in outline, but the bore is counter-bored to accept pipe. Socket welding pipe flanges are typically used on smaller sizes of high pressure pipes. Socket weld flanges are widely used in high pressure systems such as hydraulic equipment and steam lines. Socket weld pipe flanges are attached by inserting the pipe into the socket end and then applying fillet weld around the hub of the flange. This allows for a smooth bore and better flow of the fluid or gas inside of the pipe. An optional internal weld may be applied in high stress applications.

| Specification | ASTM B366, ASTM SB 366, ASTM B564, ASME SB564 |

| Grade | Alloy Steel Blind Flanges: ASTM A182 F1, F5, F9, F11, F22, F91 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/8″ to 36″/ |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

ASTM A182 F1 Flanges Manufacturer

We trade in a range of alloy steel flanges that are available at industry leading prices. Procured from leading and well established vendors, our alloy steel flanges are used in varied applications. we Offers multiple range of alloy steel ASTM A182 F1 Forged Flanges. These products have got recognition at different customer markets. stainless steel ASTM A182 F1 Forged Flanges are known for corrosion and abrasion resistance features. Our range of stainless steel ASTM A182 Forged Flanges is checked for their higher temperature resistivity, dimension, shaper, strength, corrosion resistivity and various other features that ensure optimum quality in the final product.

Grades:

- ASTM A182 F1 Flanges

- ASTM A182 F5 Flanges

- ASTM A182 F9 Flanges

- ASTM A182 F11 Flanges

- ASTM A182 F12 Flanges

- ASTM A182 F22 Flanges

- ASTM A182 F91 Flanges

Class:

- 150#

- 300#

- 400#

- 600#

- 900#

- 1500#

- 2500#

- 150 Lb

- 300 Lb

- 600 Lb

- 900 Lb

- 1500 Lb

- 2500 Lb

- 3000 PSI

- BS-10

- Standard Table: D, E, F, H DIN Standard

Standards and specification in normal terms are as under:-

- Alloy steel F1 Slip On Flanges

- Alloy steel F1 Slip On Orifice Flanges

- Alloy steel F1 Blind Flanges

- Alloy steel F1 Weld Neck Flanges

- Alloy steel F1 Long Weld Neck Flanges

- Alloy steel F1 Heavy Barrel Long Weld Neck Flanges

- Alloy steel F1 RTJ Flanges

- Alloy steel F1 Weld Neck Orifice Flanges

- Alloy steel F1 Lap Joint Flanges

- Alloy steel F1 Socket Weld Flanges

- Alloy steel F1 Threaded Flanges

- Alloy steel F1 Threaded Orifice Flanges

- Alloy steel F1 AWWA Standard Steel-ring Flanges Class B

- Alloy steel F1 AWWA Standard Steel-ring Flanges Class C

- Alloy steel F1 AWWA Standard Steel-hub Flanges Class D

- Alloy steel F1 AWWA Standard Steel-hub Flanges Class E

- Alloy steel F1 Plate Flanges

ASTM A182 F11 Flanges

We are one of the leading masters in Stocking & Importing of ASTM A182 F11 Alloy Steel Flanges Our supply chain includes India, UAE, Saudi Arabia, Kuwait, Singapore, Malaysia, Indonesia, South Africa, Iran, Netherland , Brazil.& many other Import sources who are highly Renowned and Professional manufacturers acquiring High Level of industry expertise and latest technologies. We welcome your inquiries.

astm a182 f11 flanges Production Range

| Grade/Specification | ASTM / ASME A182 F1 / F5 / F9 / F11 / F22 / F91 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | ½” to 36″ |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Product | Size | |

| Alloy Steel Slip-On Flanges | Alloy Steel Threaded Flanges | 1/8″ – 36″Raised Face or Flat Face |

| Alloy Steel Weld Neck Flanges | Alloy Steel Socket Weld Flanges | |

| Alloy Steel Blind Flanges | Alloy Steel Reducing Flanges | |

| Alloy Steel Lap Joint Flanges | Alloy Steel Plate Flanges | |

astm a182 f11 flanges Chemical Composition

Chemical composition % of astm a182 f11 flanges

|

Carbon, C

|

0.10 – 0.15 %

|

|

Chromium, Cr

|

1.0 – 1.5 %

|

|

Manganese, Mn

|

0.30 – 0.80 %

|

|

Molybdenum, Mo

|

0.44 – 0.65 %

|

|

Phosphorous, P

|

<= 0.040 %

|

|

Silicon, Si

|

0.50 – 1.0 %

|

|

Sulfur, S

|

<= 0.040 %

|

Mechanical properties of astm a182 f11 flanges

|

Hardness, Brinell

|

143 – 207

|

|

Tensile Strength, Ultimate

|

485 MPa

|

|

Tensile Strength, Yield

|

275 MPa

|

|

Elongation at Break

|

20 %

|

|

Reduction of Area

|

>= 30 %

|

ASTM A182 F12 Flanges Manufacturers

We are also manufacturer, supplier and exporter of Alloy Steel A182 F5 Fittings – A182 F5 / F9 / F11 / F12 / F22 / F91 Forged Fittings, Flanges.

A182 F5 / F9 / F11 / F12 / F22 / F91 Flanges :

Size: 1/2" TO 12 "IN OD & NB

Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS DIN Standard ND 6,10, 16, 25, 40

Specification: ASTM, ASME, API, AISI, BS, ANSI, DIN, JIS, MSSP, NACE

Materials: Alloy Steel A182 F5 Flange ASTM A182 – F5, F9, F11, F12, F21, F22 & F91

ASTM A182 F22 Flanges manufacturers

| Item | steel flange, steel pipe flanges, ASTM A182 F22 Flanges |

|---|---|

| Standard | AISI B16.5, AISI B16.47, AISI B16.36, MSS SP44, API6A, BS 4504, EN1092, UNI 2277/2278, DIN 4504 |

| Material | Alloy Steel Threaded Flanges: ASTM A182 F1, F5, F9, F11, F22, F91 |

| Type | Plate Flange, Flat Flange, Slip on Flange, Welding Neck Flange, Long Welding Neck Flange, Blind Flange, Socket Welding Flange, Thread Flange, Screwed Flange, Lap Joint Flange |

| Connection type | Raised Face, Flat Face, Ring Type Joint, Lap-Joint Face, Large Male-Female, Small Male-Female, Large Tongue, Groove, Small Tongue, Groove. |

| Size | 1/2"-100", SCH5S-SCH160, XS, XXS, STD |

| Application | Widely used in petroleum/ chemical industry/power/ship building/paper making/metallurgy/ construction /water supply and sewage work |

ASTM A182 F5 Flanges Manufacturers

| Standards | : | ANSI Flanges, ASME Flanges, API, MSSP, BS Flanges, DIN Flanges, EN Flanges, NACE etc. |

| Dimension | : | 150#, 300#, 600#, 900#, 1500#, 2500#. PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Grade | : | ASTM / ASME A182 F1 / F5 / F9 / F11 / F22 / F91. |

| Class/ Pressure | : | 150#, 300#, 400 #, 600#, 900#, 1500# & 2500# |

| Size | : | ½” to 36" |

| Wall Thickness | : | SCH.10, 20, 30, 40, 80, 120, 160, STD, XS, XXS. |

| Type | : | Slip on Flanges – SORF, Weld neck Flanges – WNRF, Socket weld Flanges – SWRF, Blind Flanges – BLRF Lapped joint Flanges, Screwed Flanges, Long weld neck Flanges, Reducing Flanges, Spectacle Flanges, Ring joint Fla |

ASTM A182 F9 Flanges Manufacturers

Specification: ASTM / ASME SB 61 / 62 / 151 / 152

Grade: ASTM / ASME A182 F1 / F5 / F9 / F11 / F22 / F91

Standard: ASME Flanges, ANSI Flanges, DIN Flanges, BS Flanges, EN Flanges, etc

Dimensions: ANSI/ASME B16.5, B 16.47 Series A & B, EN-1092, BS4504, BS 10, B16.48, DIN, etc.

Size: ½” to 12″

Class: 150#, 300#, 600#, 900#, 1500#, 2500#. PN6, PN10, PN16, PN25, PN40, PN64 etc.

Alloy steel Raised face flanges Types:

| Product | Size | |

| Alloy Steel F9 Slip-On Flanges | Alloy Steel F9 Threaded Flanges | 1/8″ – 36″Raised Face or Flat Face |

| Alloy Steel F9 Weld Neck Flanges | Alloy Steel F9 Socket Weld Flanges | |

| Alloy Steel F9 Blind Flanges | Alloy Steel F9 Reducing Flanges | |

| Alloy Steel F9 Lap Joint Flanges | Alloy Steel F9 Plate Flanges | |

ASTM A182 F91 Flanges Manufacturers

| Specification | ASTM A182 / A240 & ASME SA182 / SA240 |

| Grade | ASTM / ASME A182 F1 / F5 / F9 / F11 / F22 / F91 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/8″ to 36″/ |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

Alloy Steel flange dimensions

|

|

|

|

|

| Alloy steel ring type joint flanges | Alloy steel raised face flanges | Alloy steel Flat face flange supplier | stainless steel flange suppliers uk | stainless steel flange uae |

|

|

|

|

|

| Alloy steel collar flanges | Alloy steel flat face flanges | Alloy steel spectacle blind flange bolts | Alloy steel slip on flanges | Alloy steel threaded flanges |