Manufacturers of Socket Weld Flanges, SW Flanges Manufacturers

Our company offers a wide range of flanges like PL, SW, BL, WN,SO,LJ, Socket Welding Flange-ASME/ANSI B16.5 etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

Our company offers a wide range of flanges like PL, SW, BL, WN,SO,LJ, Socket Welding Flange-ASME/ANSI B16.5 etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

½” (15 NB) to 60” (1500NB) in 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ASA 150, ASA 300, PN 6,10,16,25, 40,64,100,160 ETC. available with NACE MR 01-75

½” (15NB) to 60” (1500NB)

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500# PN6, PN10, PN16, PN25, PN40, PN64

B16.5, BS4504, EN-1092, B16.36, B16.47, B16.48, MSS SP44

STD : ANSI Flanges, ASME Flanges, DIN Flanges, EN Flanges, BS Flanges, API, JIS, NACE etc.

Dimensional accuracy, Corrosion resistance, High efficiency, Excellent finish, Durable

Stainless Steel Socket Weld Flanges :

Standard : ASTM / ASME A/SA 182

Standard : ASTM / ASME A/SA 182 Grade : F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L

Duplex Steel Socket Weld Flanges :

Standard : ASTM / ASME A/SA 182

Standard : ASTM / ASME A/SA 182 Grade : F 44, F 45, F51, F 53, F 55, F 60, F 61

Aluminium Socket Weld Flanges :

Standard : ASTM B247, B361.

Standard : ASTM B247, B361. Grade : 2024, 6061, 6063, 6101, 7075.

Titanium Socket Weld Flanges :

Grade : Grade 1, Grade 2, Grade 4, Grade 5, Grade 6, Grade 7, Grade 9, Grade 19, Grade 23

Carbon Steel Socket Weld Flanges :

Standard : ASTM A 105/A694/ A350 LF3/A350 LF2.

Standard : ASTM A 105/A694/ A350 LF3/A350 LF2. Grade : F42/46/52/56/60/65/70

Low Temperature Carbon Steel Socket Weld Flanges :

Alloy Steel Socket Weld Flanges :

Standard : ASTM A182

Standard : ASTM A182 Grade : F1/F5/F9/F11/F22/F91

Copper Alloy Socket Weld Flanges :

Grade : UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30) C 71640

Nickel Alloy Socket Weld Flanges :

Standard : ASTM / ASME SB 564 / 160 / 472

Standard : ASTM / ASME SB 564 / 160 / 472• Nickel 200 – UNS N02200 • Nickel 201 – UNS N02201 • Monel 400 – UNS N04400

• Monel K500 – UNS N05500 • Inconel K600 – UNS N06600 • Inconel 601 – UNS N06601

• Inconel 625 – UNS N06625 • Inconel 800 – UNS N08800 • Inconel 800H – UNS N08810

• Inconel 825 – UNS N08825 • Hastelloy C276 – UNS N10276 • Alloy 20 – UNS N08020

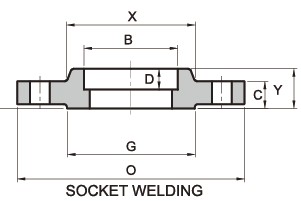

Dimensions Socket Weld Flanges & Stud Bolts ASME B16.5

This specification covers the material and dimensional requirements applicable to Socket weld flange pipe ends that are manufactured by a mechanical forming process, and are widely used for low-pressure systems in the marine, process piping, and similar industries. Materials having acceptable forming qualities to produce lap joint ends are copper, copper-nickel, titanium, carbon steel, and stainless steel.

This specification covers the material and dimensional requirements applicable to Socket weld flange pipe ends that are manufactured by a mechanical forming process, and are widely used for low-pressure systems in the marine, process piping, and similar industries. Materials having acceptable forming qualities to produce lap joint ends are copper, copper-nickel, titanium, carbon steel, and stainless steel.

| Class | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

| Diameter – A | 30 | 38 | … | 38 | … | 38 | … |

| Diameter – D | 90 | 95 | … | 95 | … | 120 | … |

| Thickness – B | 9.6 | 12.7 | … | 14.3 | … | 22.3 | … |

| 11.2 | 14.3 | … | 20.7 | … | 28.7 | … | |

| Diameter – G | 35.1 | 35.1 | … | 35.1 | … | 35.1 | … |

| Diameter – K | 60.3 | 66.7 | … | 66.7 | … | 82.6 | … |

| Height – H | 14 | 21 | … | 22 | … | 32 | … |

| 15.6 | 22.6 | … | 28.4 | … | 38.4 | … | |

| Bolt Holes | 4 | 4 | … | 4 | … | 4 | … |

| Diameter – L | 15.9 | 15.9 | … | 15.9 | … | 22.2 | … |

| Stud Bolts Diameter x Length | |||||||

| Diameter (in) | 1/2 | 1/2 | … | 1/2 | … | 3/4 | … |

| Length (mm) | 55 | 65 | … | 75 | … | 110 | … |

| NPS | 1/2 | 3/4 | 1 | 1¼ | 1½ | 2 | 2½ |

Notes:

- Dimensions are in millimeters unless otherwise indicated.

- The length of the Stud Bolt does not include the height of the chamfers (points).

- ID2 = Depending on the wall thickness of the pipe, must be specified by the purchaser.

Dimensional Tolerances of Socket Weld Flanges ASME B16.5

| Outside Diameter ≤ 24 = 1.6 mm | > 24 = ± 3.2 mm |

Inside Diameter ≤ 10 = ± 0.8 mm | ≥ 12 = + 1.6 mm / – 0 mm |

| Diameter of Contact Face 1.6 mm Raised Face = ± 0.8 mm 6.35 mm Raised Face, Tongue & Groove / Male-Female = ± 0.4 mm |

Outside Diameter of Hub ≤ 12 = + 2.4 mm / – 1.6 mm | ≥ 14 = ± 3.2 mm |

| Diameter of Counterbore Same as for Inside Diameter |

Drilling Bolt Circle = 1.6 mm | Bolt Hole Spacing = ± 0.8 mm Eccentricity of Bolt Circle with Respect to Facing ≤ 2½ = 0.8 mm max. | ≥ 3 = 1.6 mm max. |

| Thickness ≤ 18 = + 3.2 mm / – 0 | ≥ 20 = + 4.8 mm / – 0 |

Length thru Hub ≤ 18 = + 3.2 mm / – 0.8 mm | ≥ 20 = + 4.8 mm / – 1.6 mm |

Socket Weld Application, Socket Weld Flange Uses

Socket Weld flanges were initially developed for use on small-size high pressure piping. Their static strength is equal to Slip On flanges, but their fatigue strength 50% greater than double-welded Slip On flanges.

The connection with the pipe is done with 1 fillet weld, at the outside of the flange. But before welding, a space must be created between flange or fitting and pipe.

ASME B31.1 1998 127.3 Preparation for Welding (E) Socket Weld Assembly says:

In assembly of the joint before welding, the pipe or tube shall be inserted into the socket to the maximum depth and then withdrawn approximately 1/16" (1.6 mm) away from contact between the end of the pipe and the shoulder of the socket.

The purpose for the bottoming clearance in a Socket Weld is usually to reduce the residual stress at the root of the weld that could occur during solidification of the weld metal. The image shows you the X measure for the expansion gap.

Some details of Socket Weld fittings

SW Fittings are family of high pressure fittings are used in various industrial processes.

- They are used for lines conveying flammable, toxic or expensive material where no leakage can be permitted, and for steam 300 to 600 PSI.

- They are used only in conjunction with ASME Pipe and are available in the same size range.

- They are used in areas where pipe-work is permanent and are designed to provide good flow characteristics.

- They are are produced to several ASTM standards and are manufactured in accordance with ASME B16.11. The B16.11 standard covers pressure-temperature ratings, dimensions, tolerances, marking, and material requirements for forged carbon and alloy steel. Acceptable material forms are forgings, bars, seamless pipe, and seamless tubes which conform to the fittings chemical requirements, melting practices, and mechanical property requirements of ASTM A105, A182, or A350.

- They are available in three pressure ratings: Class 3000, 6000 and 9000.

Key Features:The recess on the inside diameter of the socket weld flange allows for a good fit of the pipe allowing for a smooth flow of liquid.

Socket welding flanges work well for smaller sizes and higher pressure temperature conditions. They are similar to slip-on flanges, but must specify the schedule of the pipe where they will be used for with socket welds.

ANSI B16.5 Socket Weld Flanges, ASME B.16.5 Socket Weld Pipe Flanges, DIN Socket Weld Flange

We are specialized in manufacturing high standard quality of Socket Weld Flanges. Socket welding flange, a popular type of pipe flange, was initially developed for use on small-sized high- pressure piping. The fabrication of this type of flange is similar to that of a slip-on flange. However, the internal pocket of a socket weld flange allows for a smooth bore and better fluid flow. When provided with an internal weld, the static strength of this flange is equal to slip-on flange, but the fatigue strength is 50% greater than double welding slip-on flanges. Smooth bore conditions in such a flange can easily be attained without having to bevel the flange face and, after welding, to reface the socket weld flange as would be required with slip-on flanges. For this reason, the internally welded flange is popular in chemical process piping.

We are specialized in manufacturing high standard quality of Socket Weld Flanges. Socket welding flange, a popular type of pipe flange, was initially developed for use on small-sized high- pressure piping. The fabrication of this type of flange is similar to that of a slip-on flange. However, the internal pocket of a socket weld flange allows for a smooth bore and better fluid flow. When provided with an internal weld, the static strength of this flange is equal to slip-on flange, but the fatigue strength is 50% greater than double welding slip-on flanges. Smooth bore conditions in such a flange can easily be attained without having to bevel the flange face and, after welding, to reface the socket weld flange as would be required with slip-on flanges. For this reason, the internally welded flange is popular in chemical process piping.

Steel flanges offer a way to secure metal pipe and prevent leaks and other damage. Choosing the right metal flange and other metal fittings is dependent upon what type of substance flows through the piping system. A steel flange called a Socket weld flange is designed to offer extra support and safety in certain high-pressure areas found in residential, commercial and industrial piping systems.

Socket Weld Socket Weld flanges, steel Socket Weld Socket Weld flanges are available with following specifications:

We proffer Socket Weld Flange pipe flanges that are being manufactured at our best services to companies in a range of industries including power generation, shipbuilding, petrochemical plants, waste water treatment plants, oil refineries, paper mills, turnkey projects and pharmaceutical plants among others.

Specification

Standards: ANSI B16.47 Series A & B, ANSI B16.5, API-605, MSS SP44, ASA, EN1092, BS 4504, DIN

Type: Socket Weld Flanges / Socket Weld

Size: ½” (15 NB) to 48″ (1200NB)

Class : 150 Class, 300 Class, 400 Class, 600 Class, 900 Class, 1500 Class, 2500 Class, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Material: Stainless Steel, Duplex, Super Duplex, Nickel Alloys, Alloy Steel, Carbon Steel, Low temperature Steel

Material Grade:

Stainless Steel Socket Weld Flanges: ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel Socket Weld Flanges: ASTM A182 / ASME SA182, F 44, F 45, F51, F 53, F 55, F 60, F 61

Carbon Steel Socket Weld Flanges: ASTM A105 / ASME SA105, ASTM A350 / ASME SA350, ASTM A181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70

Low Temperature Carbon Steel Socket Weld Flange (LTCS Socket Weld): Flange, A350 LF2/A350 LF3

Alloy Steel Socket Weld Flanges: ASTM A182 / ASME SA182 & A387 F1, F5, F9, F11, F12, F22, F91

Nickel Alloy Socket Weld Flanges: ASTM / ASME SB 564 / 160 / 472, UNS 2200 ( Nickel 200 ), UNS 2201 (Nickel 201 ), UNS 4400 (Monel 400 ), UNS 8020 ( Alloy 20 / 20 CB 3, UNS 8825 Inconel (825), UNS 6600 (Inconel 600 ), UNS 6601 ( Inconel 601 ), UNS 6625 (Inconel 625), UNS 10276 ( Hastelloy C 276 )

ASME B16.5 Socket Weld Flange – 150 lbs, ansi b16.5 socket weld flange dimensions , Socket Weld Flange class 150, 150lb Socket Welding Flange-ASME/ANSI B16.5/Standards, Dimensions & Weight

Specification :

Type: Socket Weld Forged Flange

Material: Carbon steel: A105,SS400,SF440 RST37.2,S235JRG2,P250GH,C22.8, Stainless Steel: F304 F304L F316 F316L 316Ti, Copper, High Nickel Alloys.

Standard: ANSI/DIN/JIS

Size: 1/2-78 inch (DN15-DN2000)

Pressure: ANSI class 150, 300, 600, 1500, 2500, DIN PN6,PN10,PN16,PN25,PN40,PN64,PN100,PN160

The wide range of ANSI B 150 Class- Socket Weld Flanges offered by us is in conformation with international quality standards. These are designed as per the standards set by various national and international authorities and are manufactured using high grade steel. Our range of flanges is highly acknowledged in the domestic and global markets, due to features such as application specific design and corrosion resistance.

Socket Weld Flanges

Class 150

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Diameter of Raised Face | Length Hub.Y | Bore | Depth of Socket.D |

Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

KG | LB | |

| inch | dn | O | C | X | G | Y | B | D | BC | BH | BN | BD | ||

| 1/2" | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 22.40 | 9.70 | 60.50 | 15.80 | 4 | 1/2" | 0.4 | 0.9 |

| 3/4" | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 27.70 | 11.20 | 69.90 | 15.80 | 4 | 1/2" | 0.7 | 1.5 |

| 1" | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 34.50 | 12.70 | 79.30 | 15.80 | 4 | 1/2" | 0.9 | 2 |

| 1-1/4" | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 43.20 | 14.20 | 88.90 | 15.80 | 4 | 1/2" | 1.2 | 2.6 |

| 1-1/2" | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 49.50 | 15.80 | 98.60 | 15.80 | 4 | 1/2" | 1.5 | 3.3 |

| 2" | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 62.00 | 17.50 | 120.70 | 19.10 | 4 | 5/8" | 2.3 | 5.1 |

| 2-1/2" | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 74.70 | 19.10 | 139.70 | 19.10 | 4 | 5/8" | 3.7 | 8.1 |

| 3" | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 90.70 | 20.60 | 152.40 | 19.10 | 4 | 5/8" | 4.2 | 9.2 |

| 3-1/2" | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 103.40 | 177.80 | 19.10 | 8 | 5/8" | 5.2 | 11.4 | |

| 4" | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 116.10 | 190.50 | 19.10 | 8 | 5/8" | 5.9 | 13 | |

| 5" | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 143.80 | 215.90 | 22.40 | 8 | 3/4" | 7 | 15.4 | |

| 6" | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 170.70 | 241.30 | 22.40 | 8 | 3/4" | 8.4 | 18.5 | |

| 8" | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 221.50 | 298.50 | 22.40 | 8 | 3/4" | 12.6 | 27.7 | |

| 10" | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 276.40 | 362.00 | 25.40 | 12 | 7/8" | 18 | 39.6 | |

| 12" | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 327.20 | 431.80 | 25.40 | 12 | 7/8" | 29.5 | 65 | |

| 14" | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 359.20 | 476.30 | 28.50 | 12 | 1" | 38 | 84 | |

| 16" | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 410.50 | 539.80 | 28.50 | 16 | 1" | 42 | 93 | |

| 18" | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 461.80 | 577.90 | 31.80 | 16 | 1 1/8" | 54 | 120 | |

| 20" | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 513.10 | 635.00 | 31.80 | 20 | 1 1/8" | 70 | 155 | |

| 24" | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 616.00 | 749.30 | 35.10 | 20 | 1 1/4" | 94 | 207 | |

300lb Socket Welding Flange-ASME/ANSI B16.5/Standards, Dimensions & Weight, class 300 socket weld flange

Socket Weld Flanges

Class 300

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Diameter of Raised Face | Length Hub.Y | Bore | Depth of Socket.D |

Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

Approx. Weight | ||

| inch | dn | O | C | X | G | Y | B | D | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2" | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 22.4 | 22.4 | 9. 7 | 66.5 | 15.7 | 4 | 1/2" | 0.7 | 1.5 |

| 3/4" | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 25.4 | 27.7 | 11.2 | 82.6 | 19.1 | 4 | 5/8" | 1.2 | 2.6 |

| 1" | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 26.9 | 34.5 | 12.7 | 88.9 | 19.1 | 4 | 5/8" | 1.4 | 3.1 |

| 1-1/4" | 32 | 133. 5 | 19.1 | 63.5 | 63.5 | 26.9 | 43.2 | 14.2 | 98.6 | 19.1 | 4 | 5/8" | 1.9 | 4.2 |

| 1-1/2" | 40 | 155. 5 | 20.6 | 69.9 | 73.2 | 30.2 | 49.5 | 15.7 | 114.3 | 22.4 | 4 | 5/8" | 2.8 | 6.2 |

| 2" | 50 | 165. 0 | 22.4 | 84.1 | 91.9 | 33.3 | 62 | 17.5 | 127 | 19.1 | 8 | 5/8" | 3.3 | 7.3 |

| 2-1/2" | 65 | 190. 5 | 25.4 | 100.1 | 104.6 | 38.1 | 74.7 | 19.1 | 149.4 | 22.4 | 8 | 3/4" | 4.6 | 10.1 |

| 3" | 80 | 209. 5 | 28.4 | 117.3 | 127 | 42.9 | 90.7 | 20.6 | 168.1 | 22.4 | 8 | 3/4" | 6.3 | 13.9 |

| 3-1/2" | 90 | 228. 5 | 30.2 | 133.4 | 139.7 | 44.5 | 103. 4 | 22.4 | 184.2 | 22.4 | 8 | 3/4" | 7.8 | 17.2 |

| 4" | 100 | 254. 0 | 31.8 | 146.1 | 157.2 | 47.8 | 116. 1 | 200.2 | 22.4 | 8 | 3/4" | 10 | 22 | |

| 5" | 125 | 279. 5 | 35.1 | 177.8 | 185.7 | 50.8 | 143. 8 | 235 | 22.4 | 8 | 3/4" | |||

| 6" | 150 | 317. 5 | 36.6 | 206.2 | 215.9 | 52.3 | 170. 7 | 269.7 | 22.4 | 12 | 3/4" | |||

| 8" | 200 | 381. 0 | 41.1 | 260.4 | 269.7 | 62 | 221. 5 | 330.2 | 25.4 | 12 | 7/8" | |||

| 10" | 250 | 444. 5 | 47.8 | 320.5 | 323.9 | 66.5 | 276. 4 | 387.4 | 28.4 | 16 | 1" | |||

| 12" | 300 | 520. 5 | 50.8 | 374.7 | 381 | 73.2 | 327. 2 | 450.9 | 31.8 | 16 | 1 1/8" | |||

| 14" | 350 | 584. 0 | 53.8 | 425.5 | 412.8 | 76.2 | 359. 2 | 514..4 | 31.8 | 20 | 1 1/8" | |||

| 16" | 400 | 647. 5 | 57.2 | 482.6 | 469.9 | 82.6 | 410. 5 | 571.5 | 35.1 | 20 | 1 1/4" | |||

| 18" | 450 | 711. 0 | 60.5 | 533.4 | 533.4 | 88.9 | 461. 8 | 628.7 | 35.1 | 24 | 1 1/4" | |||

| 20" | 500 | 774. 5 | 63.5 | 587.2 | 584.2 | 95.3 | 513. 1 | 685.8 | 35.1 | 24 | 1 1/4" | |||

| 24" | 600 | 914. 5 | 69.9 | 701.5 | 692.2 | 106. 4 | 616. 0 | 812.8 | 41.1 | 24 | 1 1/2" | |||

Note:

1) Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option.

socket weld flange class 600, 600lb Socket Welding Flange-ASME/ANSI B16.5/Standards, Dimensions & Weight

Socket Weld Flanges

Our company offers a wide range of flanges like PL, SW, BL, WN,SO,LJ, 600lb Socket Welding Flange-ASME/ANSI B16.5 etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

Class 600

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Diameter of Raised Face | Length Hub | Bore | Depth of Socket |

Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

Approx. Weight | ||

| inch | dn | O | C | X | G | Y | B | D | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2" | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 22.4 | 22.9 | 9.7 | 66.5 | 15.7 | 4 | 1/2" | 1 | 2.2 |

| 3/4" | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 25.4 | 28.2 | 11.2 | 82.6 | 19.1 | 4 | 5/8" | 1.6 | 3.5 |

| 1" | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 26.9 | 35.1 | 12.7 | 88.9 | 19.1 | 4 | 5/8" | 1.8 | 4 |

| 1-1/4" | 32 | 133. 5 | 20.6 | 63.5 | 63.5 | 28.4 | 43.7 | 14.2 | 98.6 | 19.1 | 4 | 5/8" | 2.6 | 5.7 |

| 1-1/2" | 40 | 155. 5 | 22.4 | 69.9 | 73.2 | 31.8 | 50 | 15.7 | 114.3 | 22.4 | 4 | 3/4" | 3.3 | 7.7 |

| 2" | 50 | 165. 0 | 25.4 | 84.1 | 91.9 | 36.6 | 62.5 | 17.5 | 127 | 19.1 | 8 | 5/8" | 3.9 | 8.6 |

| 2-1/2" | 65 | 190. 5 | 28.4 | 100.1 | 104.6 | 41.1 | 75.4 | 19.1 | 149.4 | 22.4 | 8 | 3/4" | 6 | 13.2 |

| 3" | 80 | 209. 5 | 31.8 | 117.3 | 127 | 46 | 91.4 | 20.6 | 168.1 | 22.4 | 8 | 3/4" | 7.4 | 16.3 |

| 3-1/2" | 90 | 228. 5 | 35.1 | 133.4 | 139.7 | 49.3 | 104.1 | 184.2 | 25.4 | 8 | 7/8" | 9.5 | 20.9 | |

| 4" | 100 | 273. 0 | 38.1 | 152.4 | 157.2 | 53.8 | 116.8 | 215.9 | 25.4 | 8 | 7/8" | |||

| 5" | 125 | 330. 0 | 44.5 | 189 | 185.7 | 60.5 | 144.5 | 266.7 | 28.4 | 8 | 1" | |||

| 6" | 150 | 355. 5 | 47.8 | 222.3 | 215.9 | 66.5 | 171.5 | 292.1 | 28.4 | 12 | 1" | |||

| 8" | 200 | 419. 0 | 55.6 | 273.1 | 269.7 | 76.2 | 222.3 | 349.3 | 31.8 | 12 | 1 1/8" | |||

| 10" | 250 | 508. 0 | 63.5 | 342.9 | 323.9 | 85.9 | 277.4 | 431.8 | 35.1 | 16 | 1 1/4" | |||

| 12" | 300 | 559. 0 | 66.5 | 400.1 | 381 | 91.9 | 328.2 | 489 | 35.1 | 20 | 1 1/4" | |||

| 14" | 350 | 603. 5 | 69.9 | 431.8 | 412.8 | 93.7 | 360.2 | 527.1 | 38.1 | 20 | 1 3/8" | |||

| 16" | 400 | 686. 0 | 76.2 | 495.3 | 469.9 | 106. 4 | 411.2 | 603.3 | 41.1 | 20 | 1 1/2" | |||

| 18" | 450 | 743. 0 | 82.6 | 546.1 | 533.4 | 117. 3 | 462.3 | 654.1 | 44.5 | 20 | 1 5/8" | |||

| 20" | 500 | 813. 0 | 88.9 | 609.6 | 584.2 | 127. 0 | 514.4 | 723.9 | 44.5 | 24 | 1 5/8" | |||

| 24" | 600 | 940. 0 | 101.6 | 717.6 | 692.2 | 139. 7 | 616 | 838.2 | 50.8 | 24 | 1 7/8" | |||

Flange – Socket Weld , ANSI Class 1500

, long welding neck flange 1500, 1500lb Socket Welding Flange-ASME/ANSI B16.5/Standards, Dimensions & Weight

- ASME Standards

- ASME B16.5 – Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard

- ASTM Standards

- ASTM A105 / A105M – Specification for Carbon Steel Forgings for Piping Applications

- Bolt circle diameters are 1/8 inch larger than bolt diameter.

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Length Hub | Bore | Depth of Socket |

Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

|

| inch | dn | O | C | X | Y | B | D | BC | BH | BN | BD |

| 1/2" | 15 | 120.7 | 22.4 | 38.1 | 31.8 | 22.4 | 9.7 | 82.6 | 22.4 | 4 | 3/4" |

| 3/4" | 20 | 130 | 25.4 | 44.5 | 35.1 | 27.7 | 11.2 | 88.9 | 22.4 | 4 | 3/4" |

| 1" | 25 | 149.4 | 28.4 | 52.3 | 41.1 | 34.5 | 12.7 | 101.6 | 25.4 | 4 | 7/8" |

| 1-1/4" | 32 | 158.8 | 28.4 | 63.5 | 41.1 | 43.2 | 14.2 | 111.3 | 25.4 | 4 | 7/8" |

| 1-1/2" | 40 | 177.8 | 31.8 | 69.9 | 44.5 | 49.5 | 15.7 | 124 | 28.4 | 4 | 1" |

| 2" | 50 | 215.9 | 38.1 | 104.6 | 57.2 | 62 | 17.5 | 165.1 | 25.4 | 8 | 7/8" |

| 2-1/2" | 65 | 244.3 | 41.1 | 124 | 63.5 | 74.7 | 19.1 | 190.5 | 28.4 | 8 | 1" |

| 3" | 80 | 266.7 | 47.8 | 133.4 | 190.5 | 25.4 | 8 | 7/8" | |||

| 4" | 100 | 311.2 | 53.8 | 162.1 | 235 | 31.8 | 8 | 1 1/8" | |||

| 5" | 125 | 374.7 | 73.2 | 196.9 | 279.4 | 35.1 | 8 | 1 1/4" | |||

| 6" | 150 | 393.7 | 82.6 | 228.6 | 317.5 | 31.8 | 12 | 1 1/8" | |||

| 8" | 200 | 482.6 | 91.9 | 292.1 | 393.7 | 38.1 | 12 | 1 3/8" | |||

| 10" | 250 | 584.2 | 108 | 368.3 | 469.9 | 38.1 | 16 | 1 3/8" | |||

| 12" | 300 | 673.1 | 124 | 450.9 | 533.4 | 38.1 | 20 | 1 3/8" | |||

| 14" | 350 | 749.3 | 133.4 | 495.3 | 558.8 | 41.1 | 20 | 1 1/2" | |||

| 16" | 400 | 825.5 | 146.1 | 552.5 | 616 | 44.5 | 20 | 1 5/8" | |||

| 18" | 450 | 914.4 | 162.1 | 596.9 | 685.8 | 50.8 | 20 | 1 7/8" | |||

| 20" | 500 | 984.3 | 177.8 | 641.4 | 749.3 | 53.8 | 20 | 2" | |||

| 24" | 600 | 1168.4 | 203.2 | 762 | 901.7 | 66.5 | 20 | 2 1/2" | |||

Note:

1) Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option.

Socket Weld Flange Specification, SW Flanges Specification

Socket Welding Flange, we supply socket weld flange, SW forged Flange, Socket Welding Flange in forged steel, Stainless Steel, AS,CS etc..

Socket Welding Flange, we supply socket weld flange, SW forged Flange, Socket Welding Flange in forged steel, Stainless Steel, AS,CS etc..

Specification of Socket Welding Flange

SW forged flange is similar to the slip-on flange, same to socket welding flange, but the bore is counter-bored to accept pipe. The diameter of the remaining bore is the same as the inside diameter of the pipe. The Socket Welding Flange is attached to the pipe by a fillet weld around the hub of the flange. An optional internal weld may be applied in high stress applications. The biggest use of Socket Flanges is in high pressure systems such as hydraulic and steam lines.

Description of Socket Welding Flange

- Type: SW Flange

- Material: Carbon steel: A105,SS400,SF440 RST37.2,S235JRG2,P250GH,C22.8, Stainless Steel: F304 F304L F316 F316L 316Ti, Copper etc.

- Standard: ANSI,JIS,DIN,BS4504,SABS1123,EN1092-1, UNI,AS2129,GOST-12820

- Size: 1/2-78 inch (DN15-DN2000)

- Pressure: ANSI class 150,300,600,1500,2500, DIN PN6,PN10,PN16,PN25,PN40,PN64,PN100,PN160

- Packing: No Fumigate or Fumigate Plywood/Wood Pallet or Case

- Surface Treatment: Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint,Zinc,Hot dipped Galvanized.

- E-catalogue: Available , please visit catalogue of flange

- Usage: Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects etc.

4″ Class 150 Socket Weld Raised Face Flange

- Bolt Diameter:5/8"

- Bolt Hole Diameter:7-1/2"

- Class:150

- Flange Outer Diameter:9.00"

- Hub Diameter:5.31"

- Length Through Hub:1.31"

- Material:Steel

- Number of Holes:8

- Pipe Size:4"

- Specification:ASTM A 105, ANSI B16.5

- Style:Raised Face

- Thickness:0.94"

- Type:Socket Weld Flange

- Product Weight: 13 lbs

Socket Weld Flange Standards, socket weld raised face flange

Stainless Steel : ASTM A 182, A 240

Grade : F304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L, Duplex stainless steel UNS S31803, 2205, Super Duplex stainless steel UNS S32750

Carbon Steel : ASTM A 105, ASTM A 181

Alloy Steel : ASTM A 182, GR F1, F11, F22, F5, F9, F91

Nickel Alloys : Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276

Copper Alloys : Copper, Brass & Gunmetal

Size : 1/8" NB TO 48"NB.

Class : 150#, 300#,400 #,600#,900#, 1500# & 2500 #.

Standard

ANSI :ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S : BS4504 , BS4504, BS1560, BS10

Socket Weld Flange Pressure Ratings, Socket Weld Flange Drawing

We are specialized in offering ASTM A182 Socket Weld Flanges which are used in various engineering applications and can be availed in various grades like Stainless Steel 304, Stainless Steel 316, Stainless Steel 317L, Stainless Steel 347, Stainless Steel 310, Inconel 600, Inconel 625, Incoloy 825, Monel 400, Monel K-500 , Monel R-405, Hastelloy C276, Hastelloy C22, Duplex Steel 2205, Super Duplex Steel 2507, Alloy steel, Carbon Steel

We are specialized in offering ASTM A182 Socket Weld Flanges which are used in various engineering applications and can be availed in various grades like Stainless Steel 304, Stainless Steel 316, Stainless Steel 317L, Stainless Steel 347, Stainless Steel 310, Inconel 600, Inconel 625, Incoloy 825, Monel 400, Monel K-500 , Monel R-405, Hastelloy C276, Hastelloy C22, Duplex Steel 2205, Super Duplex Steel 2507, Alloy steel, Carbon Steel

Socket Welding Flange, SW Forged Flanges, Socket Weld Flange Production Range

Size: 1/2″ (15 NB) to 48″ (1200NB)

Standards: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Pressure Ratings: Class 150, Class 300, Class 400, Class 600, Class 900, Class1500, Class 2500 | PN6, PN10, PN16, PN25, PN40, PN64 etc.

Socket Weld Flange price list

ANSI B16.5 RF High Pressure Stainless Steel Socket Welding SW Flange for Industry

US $5-1500 / Piece

socket weld neck reducing hub stainless steel flange

US $1-6 / Piece

1/2"-24" ASME B16.5 blind/slip on/weld/threaded/lap joint/socket welding flange

US $0.8-1000 / Piece

EN1092 Stainless Steel Socket Welding Flanges

US $3-1000 / Piece

Types of Socket Weld Flange, SW flanges Types

| • | SS 310 / 310S Socket Weld Flanges | • | Duplex Steel UNS S31803 Socket Weld Flanges |

| • | Stainless Steel 304 / 304L Socket Weld Flanges | • | Duplex Steel Socket Weld Flanges |

| • | Stainless Steel 316 / 316L Socket Weld Flanges | • | Duplex Steel UNS S32205 Socket Weld Flanges |

| • | Stailess Steel 321 / 321H Socket Weld Flanges | • | Super Duplex UNS S32750 Socket Weld Flanges |

| • | Monel 400 Socket Weld Flanges | • | Hastelloy C276 Socket Weld Flanges |

| • | SS Socket Weld Flanges | • | Steel Socket Weld Flanges |

| • | Inconel 625 Socket Weld Flanges | • | Alloy 20 Socket Weld Flanges |

| • | Cu-Ni 70/30 (C71500) Socket Weld Flanges | • | Cu-Ni 90/10 (C70600) Socket Weld Flanges |

| • | ASTM A105 Socket Weld Flanges | • | ASTM A350 LF2 / LF3 Socket Weld Flanges |

| • | Inconel 600 Socket Weld Flanges | • | Hastelloy B2 Socket Weld Flanges |

| • | SS 317 / 317L Socket Weld Flanges | • | Super Duplex Socket Weld Flanges |

| • | SS 347 Socket Weld Flanges | • | Super Duplex UNS S32950 Socket Weld Flanges |

| • | Monel K500 Socket Weld Flanges | • | Hastelloy C22 Socket Weld Flanges |

| • | Stainless Steel 446 Socket Weld Flanges | • | ANSI Socket Weld Flanges |

| • | Inconel 718 Socket Weld Flanges | • | 904L Socket Weld Flanges |

| • | Incoloy 800 Socket Weld Flanges | • | Titanium Gr 2 Socket Weld Flanges |

| • | Incoloy 825 Socket Weld Flanges | • | Titanium Gr 5 Socket Weld Flanges |